Published on 6 November 2019

Posted in

Our ATEX cleaning system has been a very popular addition to the cleaning and FM regimes of many companies in the Food and Drink space hit it first hit the market. Find out more about the impact the system made to this chain of bakeries in Scandinavia below…

The bakery building required regular cleaning on a monthly basis to remove the dusts and other materials that were settling at high-levels and causing a problem in the form of nesting moths who were attracted to the food source. These large nests of moths would take root in the rafters and beams of the building and due to the short life cycle of the particular species would require monthly cleaning to prevent the nests, prevent infestation and stop any possible contamination of the products being manufactured below.

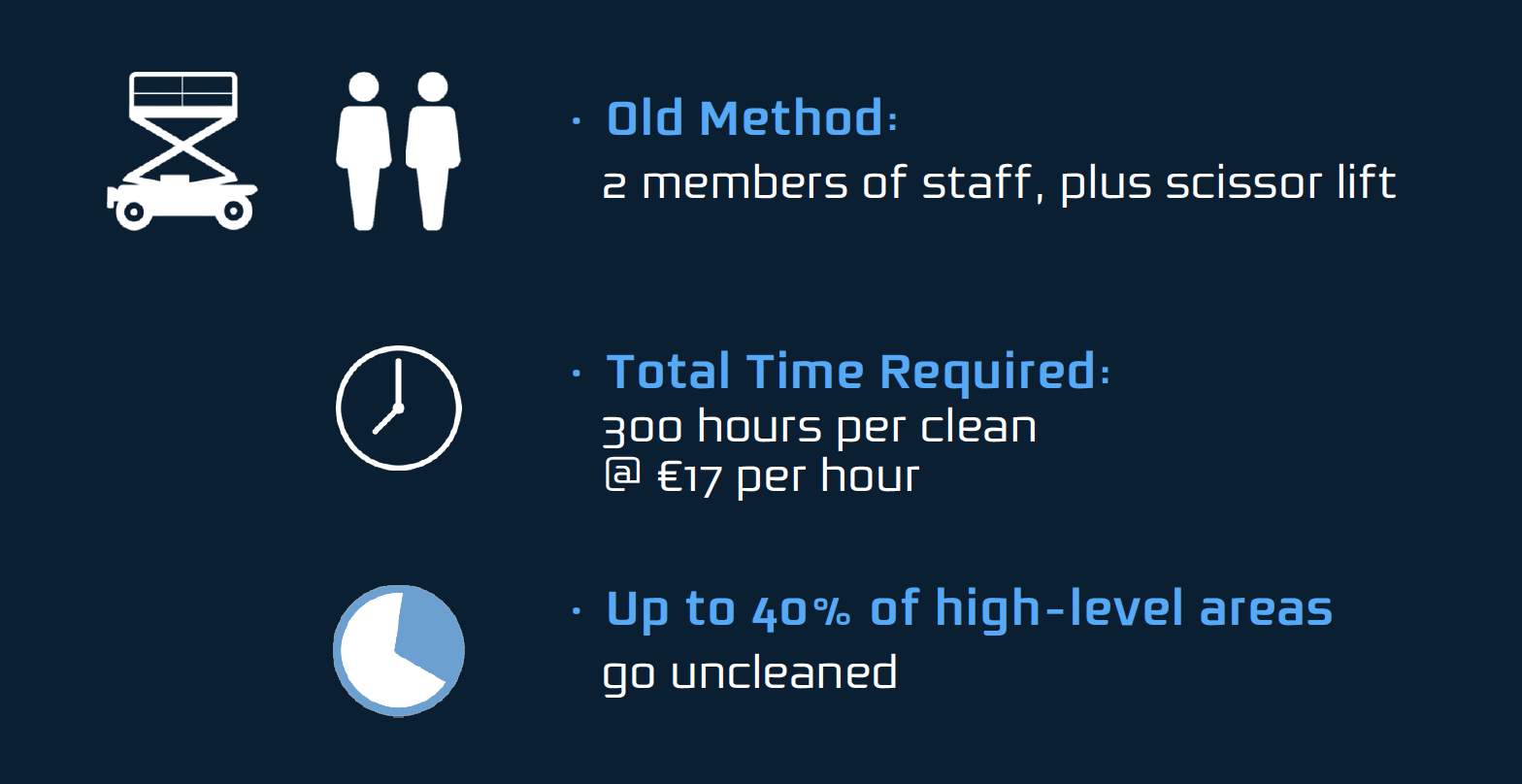

In the past, these areas of the facility were cleaned by two members of staff operating a scissor lift. This was not ideal – taking a very long time (some 300 hours every time the work was completed), and still giving the team onsite a problem – as only 40% of high-level areas were being accessed – which meant that 60% of the building was going uncleaned.

In addition to being a dangerous and time consuming job, the bakery was spending a small fortune on access equipment and man hours every month.

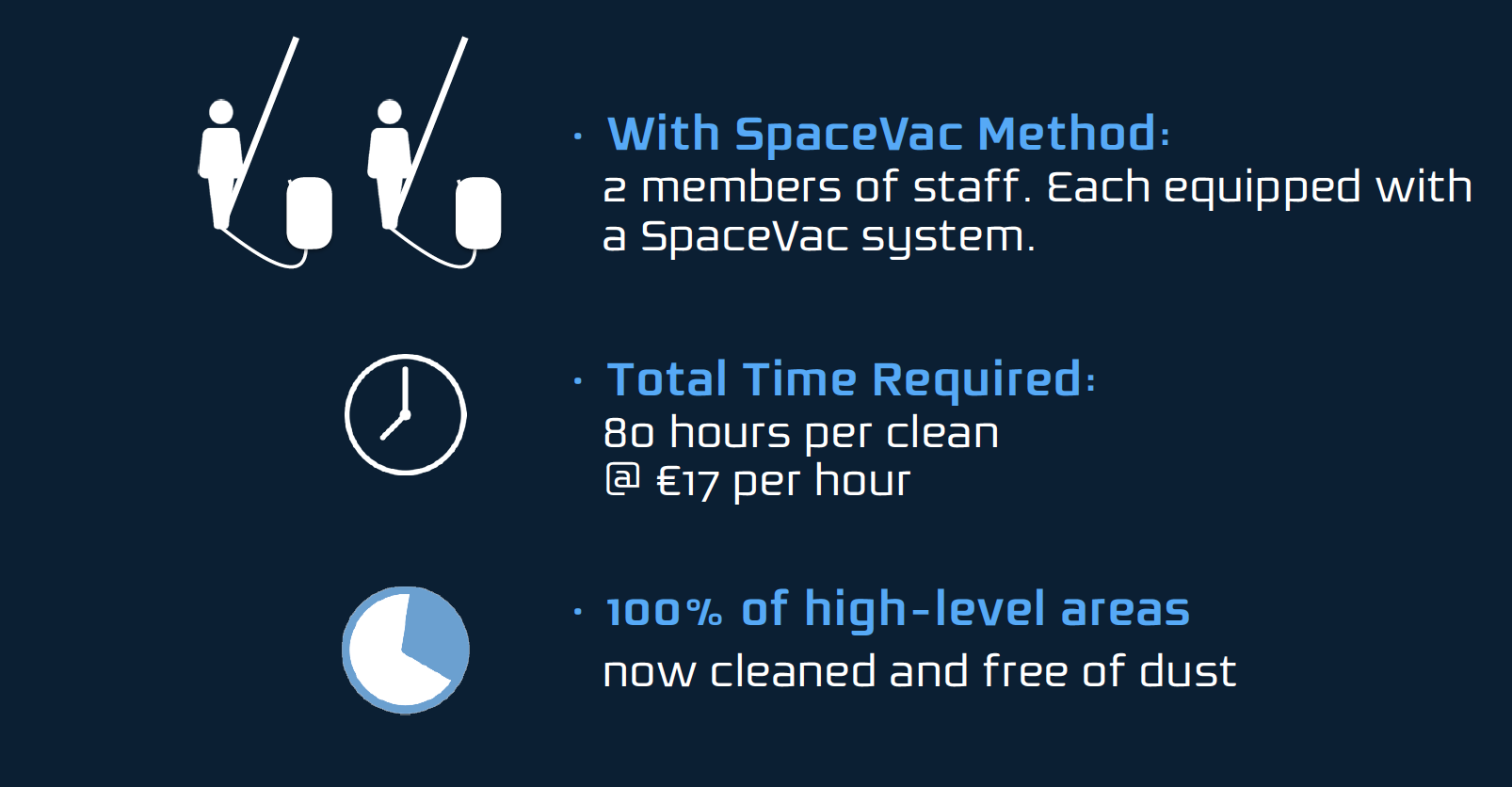

By utilising a SpaceVac however, the bakery is now able to complete the monthly cleans in a fraction of the time. By equipping two members of staff with a SpaceVac, the bakery is not only able to completely remove the risks and costs of hiring in a scissor lift to reach the high-level areas, but also reduce the cleaning time required each month to less than a third of the time previously required.

By introducing SpaceVac 100% of the facility is now clean and clear of the dust and debris and the ris of possible contamination is completely removed. In addition – the operators working onsite can enjoy peace of mind when working; knowing that the SpaceVac cleaning system they are working with, is completely conductive and has been independently tested and certified as safe for use in Explosive Division 2 atmospheres – the sorts of which are created by the spread of combustible dust.

You can see for yourself the difference a SpaceVac can make by booking a free demo on your premises today – or see the SpaceVac ATEX system in action below – recorded onsite at the above named facility last year!

© 2023 SpaceVac USA

Web Design and Marketing by Loop Digital