A dust hazard analysis is essential to ensure your workplace is safe from the potential risks of fire and explosions caused by combustible dust. They help to identify any potential areas of danger where a combustion may occur, protecting your staff, customers and workplace. A relevant plan is developed and put in place to minimise the risks once your business, operations and processes have been reviewed .

All companies that handle any kind of combustible particles must carry out a dust hazard analysis in adherence to the NFPA 652 – the standard for combustible dusts in the US.

Failing to comply could result in fines or temporary shutdowns from the Occupational Safety and Health Administration (OSHA).

Your insurance may also require you to undertake a combustible dust hazard analysis.

Dust explosions happen throughout the US in a range of different industries. Food, farming, manufacturing, metal production and chemical industries are just a few that are often at risk from dust explosions. Businesses within these industries should be aware and should have the proper protection methods in place at all times.

The key elements of a dust explosion are the same as a regular fire:

Other elements that will affect a hazard include:

The purpose of a combustible dust hazard analysis is to identify potential hazards in your workplace and improve safety. All aspects of your operations should be assessed, including handling, storage, transportation, manufacturing and production processes.

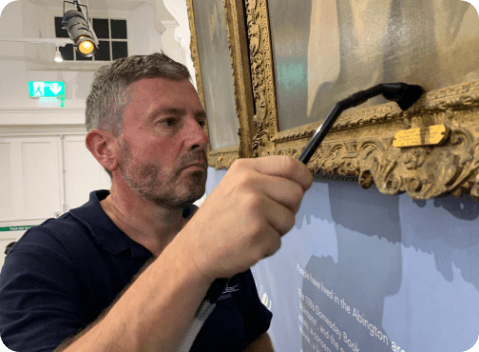

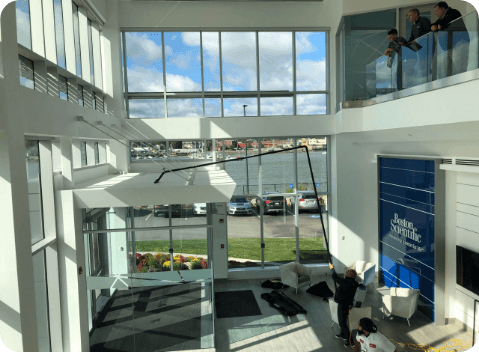

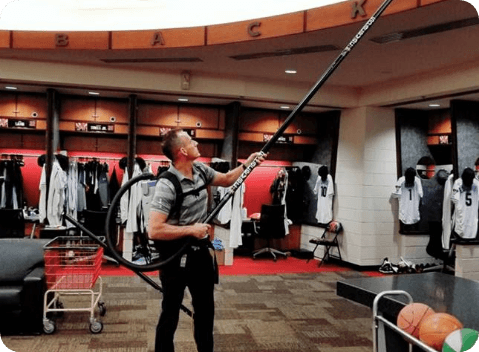

A key part of establishing a robust prevention and protection plan is to use the proper equipment during cleaning processes. Vacuums for explosive dust removal should be certified for use in Division 2 environments, meaning they guarantee a completely spark-free operation.

SpaceVac US is proud to manufacture a range of high quality vacuums that help to safely dispose of your combustible dust. Our Division 2 certified products are essential to maintaining high levels of safety in your workplace to protect your staff, customers and business from possible combustion hazards.

"Overall an excellent product. Fantastic system with lots of safety features, making it easy to use. Great service from the staff at Space-Vac."

© 2023 SpaceVac USA

Web Design and Marketing by Loop Digital