SpaceVac Ex-Proof cleaning systems were the first of their kind in the world – further cementing our reputation as a company that innovates and doesn’t imitate. We sought to design a system that built on our already impressive range of high-level cleaning equipment, but one that guaranteed spark free and anti-static usage.

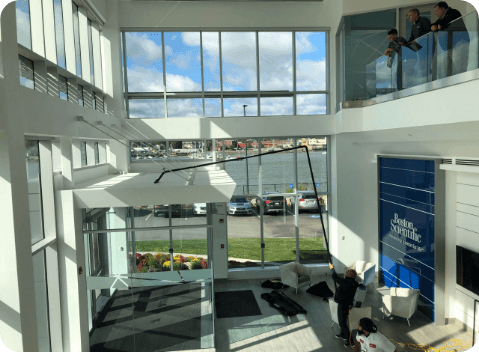

We are proud to present a full range of systems that are compliant for use in Division 2 environments. Our equipment for explosive atmospheres offer users a state-of-the-art experience in removing combustible dust in specialized combustible atmospheres. Operators can quickly and efficiently remove these hazards from high-level spaces of up to 60ft above the ground. These systems will help to keep staff, customers, company equipment and buildings safe from the risks of combustible materials

UL divisions for operating conditions are split into Division 1 and 2, with a Division 2 hazardous area containing flammable substances are not likely to be found under normal circumstances, but may be present for short periods of time.

SpaceVac USA Ex-Proof cleaning systems can be used to remove dust from potentially explosive atmospheres. Dangerous substances in the forms of gasses, vapors and dust are hazardous and can combust if an ignition point is present. Ignition may come from a spark or hot surfaces from machinery.

You will need a conductive high-level cleaning system if your business operates in potentially explosive atmospheres. This is most commonly found in manufacturing plants where daily processes result in the release of flammable gasses, or in environments that deal with fine dusts.

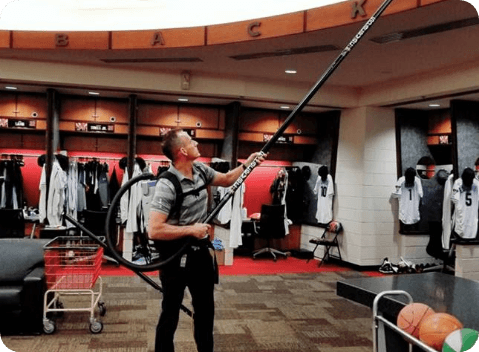

SpaceVac features a range of 6 fully conductive Division 2 certified high-level cleaning systems for you to choose from. Each one allows operators to remove combustible dust caused by flour, wood, paper and other hazards with ease.

Our Ex-Proof systems are industry leading for high-level cleaning in combustible atmospheres and feature a range of innovative features:

Alongside our Ex-Proof cleaning systems there is a full range of conductive cleaning accessories – such as heads, brushes, nozzles and more – for use in potentially explosive atmospheres.

Our Ex-Proof cleaning systems come with our very own safety locking mechanism to ensure no separation during use for maximum safety.

Our Ex-Proof cleaning systems are made from 100% full carbon to ensure conductive, non-sparking, anti-static operation. Users will be safe in the knowledge that the system is completely safe to use in explosive atmospheres where combustible dust is present.

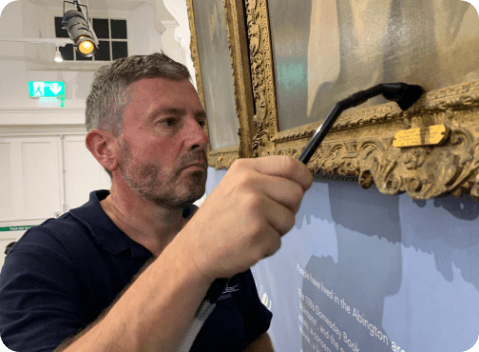

To make the cleaning process even easier and more efficient SpaceVac Ex-Proof systems are available with the addition of our camera and monitoring system. Operators are able to get a full view of where they’re cleaning from the safety of the ground below.

The Ex-Proof cameras have been independently certified for safe use in C2D2 Class 2, Division 2) areas.

Ex-proof uses classes (1 and 2) to distinguish between explosive gas and dust atmospheres. Subdivisions are then used to categorise the type of gas (A, B, C, D) and dust (E, F, G). For milling and grinding applications, the most common subdivision is G as this covers food / grain and general dusts.

To assess the likelihood of an ignitable concentration being present, the classes are allocated a division (1 or 2 – see below).

SpaceVac are Dust Safety Professional members which is a body of recommended companies.

With Spacevac you can reach many areas that more traditional methods cannot reach, so the efficiency of the clean is very much superior, saving customers on average 75% of cleaning time. Also in Ex-Proof areas, ie a bakery, the floor space is very much utilised by production lines so getting a cherry picker in is impossible the only option is usually plant shutdown and scaffolding.

"Great service, the boys did a super job. 100% recommend, will get some work done from them in the future if need be!"

© 2023 SpaceVac USA

Web Design and Marketing by Loop Digital