Why Particulate Matters When It Comes to Public Health

3 August 2021

In industrial environments, even small combustible dust hazards can make for potentially explosive conditions. Ignition sources are often common in factories and may be difficult to locate. To help reduce the risk of combustible dust regulations are in place globally to make working with dust as safe as possible.

There are five core elements that contribute to a combustible dust explosion:

Combustible dust poses a threat to many industries as a wide range of materials can become combustible. These fine particles present a high risk of explosion when combined with the following four elements.

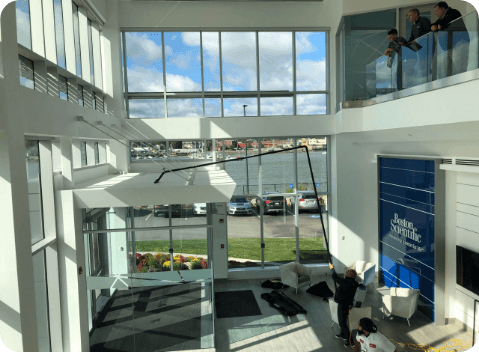

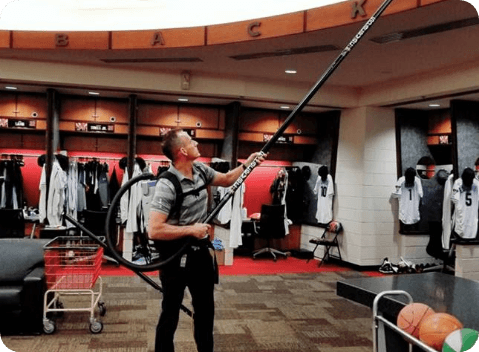

A buildup of combustible dust particles in an enclosed environment can lead to an explosion. By preventing the buildup of dust particles through regular cleaning, you reduce the risk of combustion.

A key element that leads to explosion is the buildup of dust clouds in an inclosed space. Ventilation in these instances is important, however when this is not possible due to work requirements, regular cleaning using ATEX equipment is essential.

For an explosion to occur, an oxidising agent is required. Because removing oxygen from an environment is not safe, the removal of dust is the preferred method of reducing combustion risk.

All fires and explosions require an ignition source. They come in many different forms from hot surfaces to electrostatic discharges. ATEX cleaning equipment guarantees spark free operation to ensure no ignitions occur from equipment usage.

During a risk assessment, take time to look for potential combinations of any of these factors to prevent risk of combustible dust explosions.

The National Fire Protection Association (NFPA) 652 is an objective that ensures maximum safety when working in environments where combustible dust is present. Objective NFPA 652 is a non-governmental organisation although compliance is mandatory across the US.

As a facility owner, it is your responsibility to comply with combustible dust regulations and ensure that your workplace and its equipment is safe for use. The key areas of compliance include:

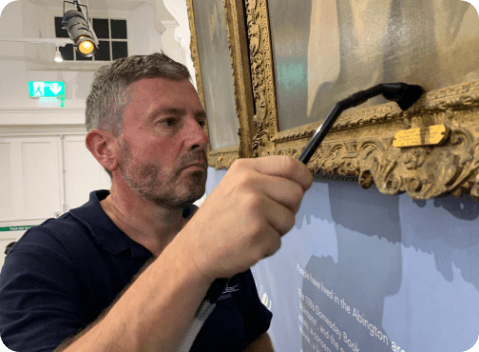

ATEX is a European certification that ensures that equipment is safe to be used on combustible materials such as hazardous dust. Equipment that is branded as ATEX certified has been rigorously tested to prove that it is safe for use in explosive environments.

For SpaceVac high level cleaning equipment, ATEX certification means that our ATEX products guarantee spark-free operation. To adhere fully to combustible dust regulations, it is essential that your equipment is ATEX certified.

"Great service, the boys did a super job. 100% recommend, will get some work done from them in the future if need be!"

© 2023 SpaceVac USA

Web Design and Marketing by Loop Digital